Why:

Online Time Recording allows mechanics to record their activities via a terminal or scanner, at order or line level, depending upon parameter ONA 001. See the parameters at the end of this topic. If there is no order for a mechanic to clock onto, the system holds a list of codes that describe downtime where the mechanic must choose one. Clocking onto an activity effectively ‘ends’ the last activity, the only time clocking ‘off’ is required is at lunch or the end of the day.

Where:

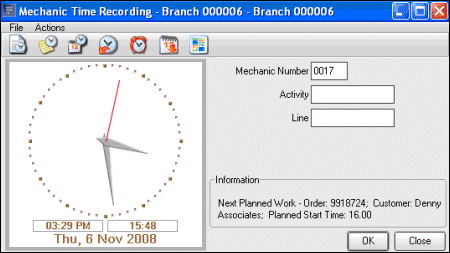

From the Mechanic View, select Actions > Online Time Recording to display the Mechanic Time Recording window. If your company uses access codes, Input your access code to proceed to the Mechanic Time Recording window.

How to Perform Online Time Recording:

If an access code was entered, then the Mechanic Number associated with this code will be established in the Mechanic Time Recording window. Once the mechanic number has been entered, either a non-productive code or an order number should be entered. If time recording is at line level, or a recording is required against straight time, then an operation number will also be required. When confirmation that an Order or Operation has been completed a dialog box will be displayed listing previous Order/Operations that have not been flagged as completed. Click OK and a message will be displayed confirming the non-productive code or order clocked onto, along with a date and time. When planning is active (parameter PLN003 is positive) and the user enters the mechanic number, a message will display in the information area to suggest the next planned order/operation to clock onto. In the example below mechanic 17 is shown an information message about work planned to start at 16:00. Once the user has clocked on, the suggested next order/operation message is replaced with the current clocking details message.

Note! The information

messages shown here relate to the Workshop Plan Details screen, see Planning.

Note! The information

messages shown here relate to the Workshop Plan Details screen, see Planning.

What else would you like to do?

Learn about Manual Time Recording.

Review Time Recording Rules.

Learn about Additional Payments in Online Time Recording.

Related Topics:

The Mechanic Master File.

Parameters:

|

Parameter Name |

Purpose / Description |

|

REC 701 |

This is used to determine if access control is set up. If yes, access codes are required before time recording can be accessed. |

|

ONA 001 |

This controls if time recording is done at order line level. |

|

ONA 002 |

This allows time to be booked against the order or line (to allow time recording against Straight time operations only). |

|

REC 201 |

This controls if a completed flag is required (0 = not used, 1 = used at order level, 2 = used at line level). |

|

BOH |

At Branch Level, this controls if barcodes are used in online time recording. |

|

REC0 & REC1 |

At Branch Level, this determines the time difference from AS400 time to region time |

|

TIM 006 |

This determines if ‘fixed’ breaks are inserted when

XFNSH is added. |

|

PLN 003 |

This activates the interface to Fusion Workshop Planning. |