Why:

A Stock Robot is a moving part shelf system. It is designed for space efficiency and rapid retrieval of parts. In Volvo markets where Stock Robots are used, they can account for between 10 to 80% of the total dealer stock holding. GDS will send Part information to and from Stock Robot at various trigger points for parts that are located in a Stock Robot. These will include Goods Receipt, Orders, IBT, Buyback, Stock Taking, and Location Change

Note! This should only be

introduced where a stock robot will be utilized.

Note! This should only be

introduced where a stock robot will be utilized.

Where:

Once all of the relevant parameters, and interface have been set up, including the control file table for Stock Robot Validation, all of the following areas where parts are flagged as being in stock robot will be affected: Parts Orders and Workshop Orders, Manual Goods Receiving and DSP, Inter Branch Transfers (out and receipt), Buy Back, Stock Adjustment and write off, Stocktaking.

How:

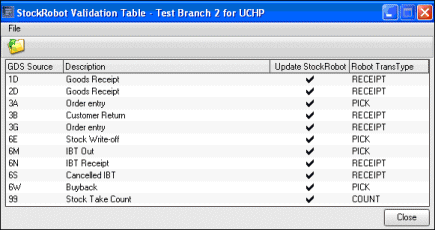

One of the location fields on The Parts Master File is used to store the name of the robot, a new field holds the stock robots id number. The following screen shows the Stock Robot validation table which will be included in the initial set up. The column ‘Update Stock Robot’ will be checked based on which specific transactions are to be carried out.

Note! Type 6E could apply

to stock adjustments as well as stock write-off. For stock adjustments we do not

send transactions to Robot, but for Stock write-off we do. Any code above 62 is

ignored for type 6E – this is ‘hard-coded’ in the program. Type 99 is hard coded

into the program as discrepancy codes do not exist for stock take

count.

Note! Type 6E could apply

to stock adjustments as well as stock write-off. For stock adjustments we do not

send transactions to Robot, but for Stock write-off we do. Any code above 62 is

ignored for type 6E – this is ‘hard-coded’ in the program. Type 99 is hard coded

into the program as discrepancy codes do not exist for stock take

count.